GD runtuyan diafragma compressor tabel parameter

Xuzhou Huayan Gas Equipment Co., Ltd.nyaéta panyadia global utama solusi komprési gas. Kalawan akumulasi kaahlian dina rarancang jeung manufaktur Manjang dekade, parusahaan urang mibanda kamampuhan produksi komprehensif ngawengku forging profésional, casting, perlakuan panas, las, machining precision, nguji assembly, sarta prosés verifikasi kualitas. Dirojong ku tim téknis khusus 120 profésional sareng fasilitas manufaktur 90,000 m², kami ngajaga alat-alat uji téknis canggih sareng metode kontrol kualitas anu ketat pikeun mastikeun kinerja produk anu unggul.

Sanggup ngarancang, manufaktur, sareng masang alat-alat dumasar kana parameter palanggan khusus, ayeuna urang ngahontal kapasitas produksi taunan 500 unit compressor gas. Kaunggulan téknis kami ngamungkinkeun pamekaran compressor kalayan tekanan ngaleupaskeun dugi ka 100MPa, nyumponan sarat industri anu paling nungtut.

Kalawan tapak suku global ngalegaan ka leuwih 50 nagara sakuliah lima buana, kaasup pasar konci kayaning Indonesia, Mesir, Vietnam, Koréa Kidul, Thailand, Finlandia, Australia, Céko, Ukraina, jeung Rusia, kami nganteurkeun solusi turnkey lengkep pikeun klien sakuliah dunya. Komitmen kami pikeun kaunggulan operasional ngajamin unggal palanggan nampi alat-alat kinerja tinggi dipasangkeun sareng dukungan téknis profésional sareng jasa responsif.

méter pasagi

TIM Téknis

Pangalaman manufaktur

NEGARA EXPORTING

A compressor diafragmamangrupakeun compressor kapindahan positif husus renowned pikeun kamampuhna pikeun nanganan gas kalayan purity luar biasa, sensitipitas, atawa bahya tanpa kontaminasi atawa leakage. Beda sareng kompresor piston tradisional, éta ngagunakeun diafragma anu fleksibel, digerakkeun sacara hidraulik pikeun ngasingkeun gas anu dikomprés tina crankcase sareng piston anu lubricated.

Fitur konci:

1,Hermetic Sealing: Logam atawa elastomer diafragma nyiptakeun lengkep, halangan bocor-bukti antara gas jeung cairan hidrolik / pelumas. Ieu mangrupikeun ciri anu ngahartikeunana.

2.Nol Kontaminasi: Ngajamin gas anu dikomprés tetep bébas minyak sareng teu kacemar ku pelumas atanapi ngagem partikel tina mékanisme drive. Penting pikeun aplikasi-purity tinggi.

3.Nyegah bocor: Sacara praktis ngaleungitkeun émisi buronan, sahingga penting pikeun nanganan gas beracun, gampang kaduruk, ngabeledug, atanapi ngabahayakeun lingkungan.

4.Kamampuhan Tekanan Tinggi: Sanggup achieving tekanan ngurangan pisan tinggi (sering nepi ka 3000 bar / 43.500 psi tur saluareun), utamana dina konfigurasi multi-tahap.

5.Nanganan Gas serbaguna: Cocog jeung compressing rupa-rupa gas, kaasup kacida réaktif, corrosive, ultra-murni, mahal, atawa tipe picilakaeun nu bakal ngaruksak atawa kacemar ku desain compressor séjén.

6.Laju Aliran Sedeng: Ilaharna dirancang pikeun laju aliran low mun sedeng dibandingkeun badag reciprocating atanapi centrifugal compressors.

Gas anu cocog

Gas anu cocog

1,Pétrokimia & Pangolahan Kimia: Komprési perantara anu kacida korosif, réaktan toksik (contona, dina produksi PVC kalawan Cl₂), gas regenerasi katalis, komprési hidrogén pikeun hydrocrackers/hydrotreaters dimana purity kritis.

2.Minyak & Gas: komprési gas subsea, suntik gas (ditingkatkeun recovery minyak), komprési hidrogén pikeun refineries.

3.Manufaktur Semikonduktor: Penting pikeun nyayogikeun kamurnian ultra luhur (UHP) sareng gas khusus anu ngabahayakeun (sapertos AsH₃, PH₃, SiH₄) kana alat fabrikasi tanpa kontaminasi.

4.Analitik & Laboratorium: Nyayogikeun gas pembawa murni, bebas kontaminan, gas kalibrasi, sareng gas sampel kanggo instrumen sapertos GC-MS.

5.Aerospace & Tés: Pasokan gas tekanan tinggi (He, N₂) pikeun nguji komponén rokét, sistem pressurizing, torowongan angin.

6.Médis & Farmasi: Produksi jeung bottling gas médis-purity luhur (O₂, N₂O), hawa steril pikeun prosés.

7.Industri Nuklir: Nanganan coolants hélium atawa gas panutup.

8.Énergi & Hidrogen: Komprési hidrogén pikeun sél suluh, stasiun ngeusian bahan bakar hidrogén (HRS), jeung produksi hidrogén / panalungtikan gudang.

9.Téhnologi Lingkungan: Compressing direbut CO₂ pikeun sequestration atanapi utilization (CCUS).

| Modél | Cai tiis (L/h) | Aliran (Nm³/h) | Tekanan Inlet (MPa) | Tekanan kaluaran (MPa) | Ukuran L×W×H(mm) | Beurat (Kg) | Daya Motor (kW) | |

| 1 | GD-120/4-80 | 3000 | 120 | 0.4 | 8.0 | 3000×1600×1400 | 4000 | 30 |

| 2 | GD-130 / 0.98-11 | 3000 | 130 | 0.098 | 1.1 | 3000×1800×1600 | 4000 | 30 |

| 3 | GD-150/2-20 | 3000 | 150 | 0.2 | 2.0 | 3000×1800×1600 | 4000 | 37 |

| 4 | GD-100 / 0.1-5 | 4000 | 100 | 0.01 | 0.5 | 2800 × 1500 × 1500 | 3000 | 18.5 |

| 5 | GD-100 / 5,5-200 | 5000 | 100 | 0.55 | 20 | 3200 × 2000 × 1600 | 4500 | 45 |

| 6 | GD-80 / 0.12-4 | 5000 | 80 | 0.012 | 0.4 | 2800 × 1600 × 1500 | 3800 | 15 |

| 7 | GD-60 / 0.3-6 | 4000 | 60 | 0.03 | 0.6 | 2800 × 1600 × 1500 | 4000 | 15 |

| 8 | GD-70 / 0.1-8 | ,3800 | 70 | 0.01 | 0.8 | 3000 × 1600 × 1250 | 5000 | 18.5 |

| 9 | GD-40 / 0.02-160 | 5000 | 40 | 0.02 | 16 | 2800 × 1460 × 1530 | 3000 | 22 |

| 10 | GD-100 / 0,5-6 | 2000 | 100 | 0.05 | 0.6 | 3000 × 2000 × 1560 | 6000 | 18.5 |

| 11 | GD-36/1-150 | 4000 | 36 | 0.1 | 15 | 3000 × 1500 × 1500 | 4000 | 45 |

| 12 | GD-35 / 0,7-300 | 4000 | 35 | 0.07 | 30 | 3000×1600×1500 | 4000 | 22 |

Urang ngayakeun sertifikasi diakuan sacara internasional kaasupCEjeungISOstandar (diakreditasi kuIAF), sakumaha ogéECMpangakuan minuhan. Sertifikasi ieu nunjukkeun komitmen urang anu teu kaampeuh kana kualitas, kaamanan, sareng tanggung jawab lingkungan:

- Nyirian CEmastikeun patuh kana peraturan kaamanan, kaséhatan, sareng lingkungan EU, ngajamin aksés pasar gratis di Éropa.

- Sertifikasi ISO(didukung ku akreditasi IAF) ngesahkeun patuh urang kana sistem manajemen kualitas anu tolok ukur sacara global, ningkatkeun konsistensi operasional sareng kapercayaan pelanggan.

- ECM Pangakuannegeskeun alignment kami sareng standar téknis sareng kinerja khusus industri.

Upami pasar atanapi proyek anjeun peryogi sertifikasi tambahan (contona,API,ASME, atanapi persetujuan khusus daérah), tim téknis sareng patuh anu berpengalaman kami bakal kolaborasi sareng anjeun pikeun éfisién kéngingkeun sertifikasi anu diperyogikeun. Kami nyaluyukeun prosés kami pikeun nyumponan sarat pangaturan anjeun, mastikeun asupna pasar anu lancar pikeun alat kami.Pikeun rojongan sertifikasi atanapi klarifikasi, mangga ngahubungan kami pikeun ngabahas solusi ngaropéa.

Urang90.000+ Méter pasagifasilitas produksi modern, staffed ku120+professional, delivers solusi rékayasa ngaropéa kalawan kamampuhan manufaktur precision. Dilengkepan 20 puseur machining CNC canggih, urang nanganan workpieces nepi ka1200 mmdiaméterna kalayan akurasi tingkat mikron (0,01 mm). Protokol kontrol kualitas anu ketat kalebet pamariksaan lengkep komponén kritis nganggo CMM (Mesin Ukur Koordinat) sareng uji beban multi-fase ku insinyur anu disertipikasi pasca-majelis. Unggal unit ngalaman validasi kinerja pikeun sasuai jeung ASME / standar API jeung spésifikasi klien, dijieun kuISO 9001-Certifiedmanajemén kualitas pikeun traceable, pangiriman dipercaya.

Urang ngamangpaatkeunfumigation-gratiskerangka kayu padetCertified ku ékspor internasional ISOstandar karantina. Dikuatkeun sacara internal ku baja saluran pikeun pangrojong tilu diménsi, bagian luar dibungkus ku penjaga sudut logam anu kandel 0.8mm sareng diamankeun dina sambungan nganggo.tali baja galvanized waterproof. Desain ieu mastikeun résistansi dampak, daya tahan komprési, panyalindungan Uap, sareng pencegahan karat sapanjang transit, ngajamin barang anjeun dugi ka aman.

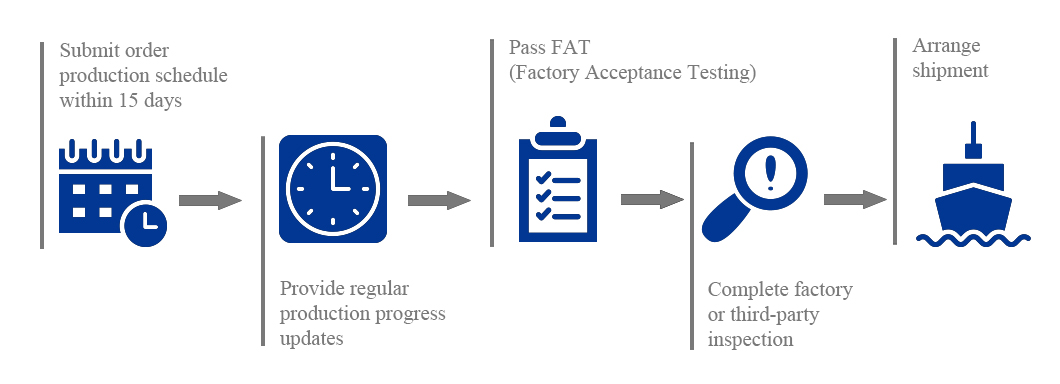

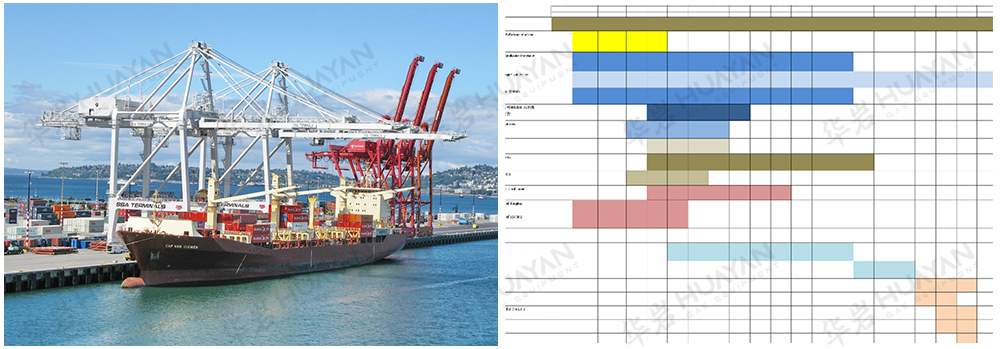

Perusahaan kami bakal ngembangkeun jadwal pangiriman khusus pikeun proyék anjeun, dirojong ku solusi logistik terpaduangkutan udara, laut, jeung darat.

Ngamangpaatkeun jaringan domestik Cina jeung partnerships global, urang mastikeun operasi cross-wates efisien kalayan tracking real-time, rojongan clearance adat, jeung kamampuhan gudang kabeungkeut. kalenturan multi-modal ngajamin ongkos-éféktif jeung pangiriman timely pikeun sakabéh jenis kargo.

1.How pikeun meunangkeun petik ajakan tina compressor gas?

1) Laju Aliran/Kapasitas : ___ Nm3/jam

2) Tekanan Nyeuseup/ Inlet : ____ Bar

3) Discharge / Outlet Tekanan: ____ Bar

4) Sedeng Gas :_____

5)Tegangan jeung Frékuénsi: ____ V/PH/HZ

2. Sabaraha lami waktos pangiriman?

Waktu pangiriman sakitar 30-90 dinten.

3.What ngeunaan tegangan produk? Tiasa aranjeunna ngaropéa?

Sumuhun, tegangan bisa ngaropéa nurutkeun inquire Anjeun.

4.Can anjeun nampi pesenan OEM?

Leres, pesenan OEM pisan wilujeng sumping.

5.Will anjeun nyadiakeun sababaraha suku cadang mesin?

Sumuhun